Large amount of limestone is used as building material and important raw material for many industries. It is widely applied in various fields, such as highway, high-speed railway, rural-way, building sand, it is an ideal material in the construction industry.

Limestone Crusher Plant For Sale

Limestone Crusher Plant For Sale -

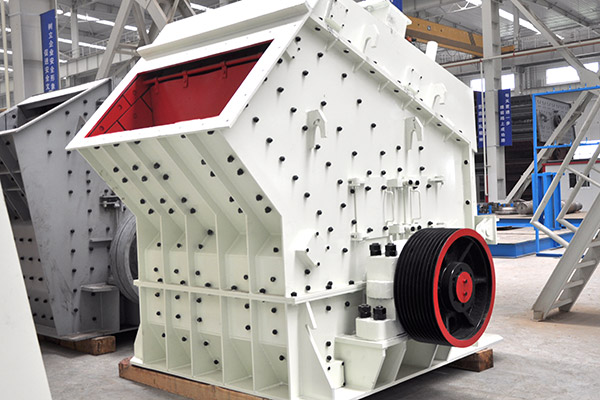

Limestone impact Crusher Plant

Limestone impact Crusher Plant -

Limestone Crusher Plant

Limestone Crusher Plant

Advantages of PF impact Crusher:

The hammer bar is made of high chromium material and wear-resistant materials. After heat treatment, it has good resistance to mechanical and thermal shock.

A self-weight safety device is equipped. When unbreakable materials enter the crushing cavity, they'll be discharged automatically, and thereby the equipment can get protected.

Important parameters PF-1520

The maximum input size: 830×2050

The output size: 20-200mm

The working process

The crushing plant process includes: silo-vibrating feeder-jaw crusher-impact crusher-circular vibrating screen-final product

First primary crushing

The limestone of the original material passes through the silo, it is uniformly fed by the vibrating feeder, and transported to the jaw crusher for primary crushing. The material after the primary crushing and the fine material screened by the vibrating feeder are transported to the compact crusher together with the belt conveyor.

Medium crushing and fine crushing

After the rough crushing, material transported to the impact crusher is crushed, the limestone after impact crusher and crushing is screened by circular vibrating screen: the larger particle limestone is returned to the impact crusher and crush again.

Final product

And the grain size qualified material is graded according to the demand and transmitted by the belt conveyor to the stock piles or transported directly to the construction site by the truck.

Advantages of limestone crusher plant

Good grain shape of final product

Most of the finished limestone particles treated by the crushing production line are cubes, which is helpful to deep processing limestone in the later stage.

Scientific and simple technological process

The process flow of the production line is simple, scientific and reasonable, smooth operation.

Reasonable and suitable equipment configuration

The complete equipment configuration, and equipment collocation of limestone crushing production line are reasonable, which is beneficial to limestone crushing.

Less pollution, less noise

Lime stone crushing production line is equipped with high-tech sealing device, resulting less dust pollution, less noise and good environmental protection performance.

Safe operation of aggregate crushing plant

Preparation before work

Before the operation, check whether the supporting equipment can run normally, such as crusher, feeder, and so on, whether the connection of these supporting equipment is loose or falling off, and whether the transmission device is abnormal. Especially the crusher, ensure that there is no residual materials in the crusher. In addition, because the working environment of the stone crushing plant is complex, the tire of the mobile crushing station is a vulnerable part, the user should also check whether the tires can work normally before carrying out the operation, so as to ensure the overall performance and normal operation.

During the process of operation

After the normal running, the operator must operate the equipment according to the correct operation regulations, and forbid overload operation.

The circuit problem of the whole machine in the operation process is a problem that the user needs to pay attention to. If there are special noises, odors or sparks in the working process, stop the operation immediately, maintain in time and never work by force. Otherwise, the whole equipment and motor may be damaged, and it is easy to cause inestimable losses to the user.

After operation

Before the stop of the crushing plant, the user must ensure that all the equipment can stop after all the materials are discharged. After the mobile crusher stops, the user should also check the circuit of the equipment, the supporting equipment and lubrication in time. For any abnormal condition, repair and maintain in time. In addition, due to the complexity of the working environment of the aggregate crushing plant, users need to clean and maintain the equipment in time after operation.

Inquiry

Inquiry