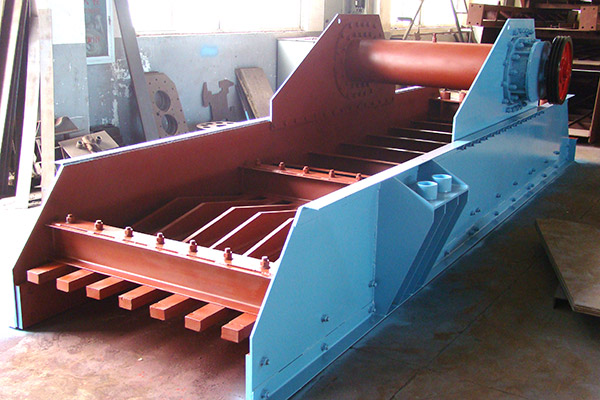

vibrating feeder

-

vibrating feeder

-

vibrating feeder

Performance

1.Big feeding ability, high efficiency

The TSW series vibrating feeder all adopts the 4-pole motor which can enhance the rotary speed of the eccentric shaft immensely; The 2-stage grid bars and the installation angle highly promote the feeding ability and the working efficiency; With larger size and higher capacity, TSW series vibrating feeder can meet the requirements of efficient and intensive industrial production.

2. Adjustment control is convenient and accurate

TSW series feeder adopts Y series motor and frequency conversion controller, which is easy to adjust and more accurate in speed adjustment.

3. High reliability with enhanced supporting device design

Side plate and rear supporting board of the feeder adopt 16Mn steel plate; bottom plate and side guard plate adopt NM360 steel plate, which has high strength. It improves the body wear, and deduces the maintenance. The bar adopts ZGMn13-4 steel plate, which has stronger structure bearing, and lengthens the life.

4. stable operation, easy maintenance

TSW feeder has simple and compact structure, small size, light weight, motor undercarriage fixed to the foundation, does not participate in vibration, increasing the reliability of equipment operation.

Specification

| Model | Max. feeding size(mm) |

Capacity (t/h) | Rotation speed (rpm) |

Groove size (mm) | Weight(kg) | Dimension (mm) |

| TSW0936 | 500 | 130-280 | 750-900 | 960×3600 | 3.95 | 3680×2136×1953 |

| TSW1139 | 600 | 150-350 | 750-900 | 1100×3900 | 4.32 | 3980×2276×1953 |

| TSW1345 | 700 | 250-450 | 750-900 | 1300×4500 | 4.97 | 4580×2570×1980 |

| TSW1548 | 850 | 350-650 | 750-900 | 1500×4800 | 6.57 | 4880×2832×2044 |

| TSW1852 | 1000 | 450-850 | 740-860 | 1800×5200 | 7.43 | 5280×3145×2059 |

| TSW2156 | 1150 | 650-1000 | 700-850 | 2100×5600 | 9.86 | 5680X3520X2359 |

Inquiry

Inquiry