-

Sand macking machine

-

Sand macking machine

-

Sand macking machine

Performance

1.Advanced double pump oil lubrication system minimizes the maintenance frequency.2.High precision roller bearing, smooth main unit running, and long service time.

3.Hydraulic lift cap, easy and convenient replacement and maintenance.

4.Over vibration alarm system.

5.Special dustproof seal system, outside powder is prevented from entering nozzles .

6.Unique feeding method, change between central feeding and central feeding with cascade

7.feeding makes rock on rock and rock on iron possible, both crushing and shaping are achieved.

8.Particular material throw head design and reasonable material selection prolongs the service time.

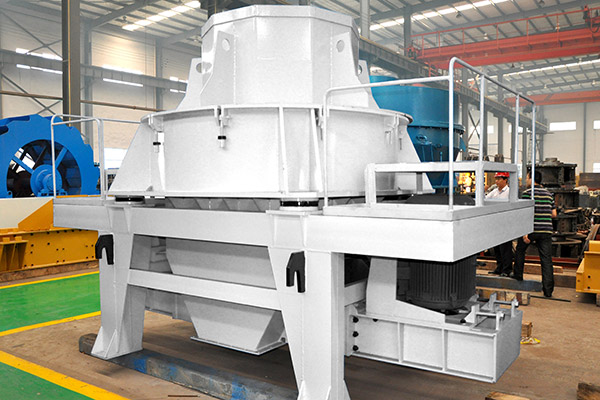

VSI5 crusher

VSI crusher is a machine that produces high efficiency sands, which is developed after several technical improvements, based on the introduction of advanced German technology.

It is the Preferred option in the field of the manufacture of artificial sands and the modeling of aggregates.

Model: VSI5X7615, VSI5X8522, VSI5X9532 ,VSI5X1145

weight(t) 8.6 ,11.8 ,17.5, 27.5

Overall dimension L*W*H (mm) :3700×2200×2300 ,4140×2300×2700, 4560×2500×2900, 5000×2700×3400

Materials to Process: limestone, coal, gypsum, seeds etc, not for very hard materials.

Applied in secondary or tertiary stage of crushing

Advantages of VSI crusher

VSI crusher is a machine that produces high efficiency sands, which is developed after several technical improvements, based on the introduction of advanced German technology.

It is the Preferred option in the field of the manufacture of artificial sands and the modeling of aggregates.

Production capacity: 30-800t / h

Maximum input size: ≤800mm

Materials to Process: limestone, coal, gypsum, seeds etc, not for very hard materials.

Applied in secondary or tertiary stage of crushing

Process flow of Vertical Shaft Impact Crushers

Material falls down into high rolling impeller cavity vertically through the upper part of machine. Under great centrifugal force, it hits and crushes another part of material that distributing around the impeller with umbrella form. After hitting each other, they force a vortex between impeller and shell, and hit each other several times; finally smaller stone comes out, and goes to vibrating screen. Satisfactory material is transported by conveyor belt. However overlarge material will go back to VI Series Vertical Shaft Impact Crushers to be re-crushed. Otherwise, output sizes can be also adjusted according to customer's requirement.Specification

| Model |

Max Feed Size (mm) |

Rotor Speed (r/min) |

Capacity (t/h) |

Motor (kw) |

Dimensions (mm) |

Weight (kg) |

|---|---|---|---|---|---|---|

| VSI-3000 | 45(70) | 1760-2210 | 30-60 | 55-90 | 30 | ≤5555 |

| VSI-4000 | 55(70) | 1550-1940 | 50-90 | 110-150 | 55 | ≤7020 |

| VSI-5000 | 65(80) | 1330-1670 | 80-150 | 150-220 | 55-75 | ≤11650 |

| VSI-6000 | 70(100) | 1190-1490 | 120-250 | 220-320 | 90-110 | ≤15100 |

| VSI-7000 | 70(100) | 1050-1310 | 180-350 | 264-400 | 90-110 | ≤17090 |

| VSI-8000 | 70(100) | 1330-1670 | 250-380 | 320-440 | 90-110 | ≤18495 |

| VSI-8000 I | 80(120) | 940-1170 | 320-600 | 440-630 | 110-132 | ≤24610 |

Inquiry

Inquiry