Sand macking machine

-

Screening & Washing

-

crusher plant sale

Features of Sand making plant

Advanced dual-pump oil lubrication system minimizes the frequency of maintenance.Highly-precise roller bearing, smooth running of main units, and long service time.

Hydraulic lifting cap, easy and convenient replacement and maintenance.

Vibration alarm system.

Special dustproof seal system. Powder is prevented from entering nozzles.

Unique feeding methods of “feeding at center” and “feeding at center and sides” make “rock on rock” and “rock on iron” possible. Crushing and shaping can be achieved simultaneously.

Sand making process flow

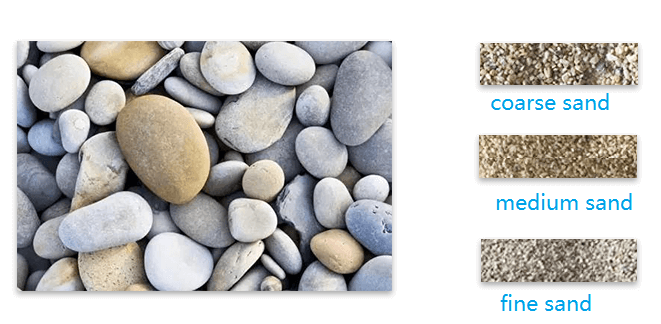

The pebble stone raw material has large reserves and wide sources. The sand production process is simple and the investment cost is low. The finished goose egg grit is uniform and round, the gradation is reasonable, the fineness modulus is adjustable, and the stone powder content is low, which is high-quality mechanism sand. The advantages of the series and so on have prompted the pebble stone sand making the project to be more valued by users, providing more sand and gravel aggregates for infrastructure and bridges.

Sand making process

A typical sand making progress in production line .Sand making production line consists of vibrating feeder, Jaw Crusher, Cone Crusher, Impact Crusher (sand-maker), vibrating screen, sand washer (sand classifier), belt conveyor, water treatment system and centralized electronic control system. We could also add a dust separator to the line to meet the specific requirements of our clients. We could assemble the production line according to the requirements of various processes to ensure the line has the best performance.

50-100TPH pebble artificial sand making line

| Equipment | Models | Quantity (Set) |

| Vibrating feeder | DN380*95 | 1 |

| GP cone crusher | DP100S | 1 |

| VSI sand making machine | VSI7611 | 1 |

| Vibrating screen | 3YD1860 | 1 |

| Wheel type sand washer | XS30016 | 1 |

Sand making production line

Sand making plants are operating as followings:

Firstly, the materials go to primary crusher (Jaw crusher) for primary crushing. Then the materials are transferred by the belt conveyor to secondary crusher (Cone crusher) for further crushing.

Then the vibrating screen will grade the materials, where stones that meet the granularity standard will be sent to VSI crusher (sand-maker), while the rest will be returned for another round of crushing.

Part of the stones processed by VSI crusher (sand maker) will be made into sand and become sand products after being washed. The rest will be further crushed by the sand maker into qualified sand materials of various types.

Sand making production line

Main equipment lists in sand making process:

jaw crusher,

cone crusher,

impact crusher(sand maker),

VSI sand maker,sand washing machine,

vibrating feeder,

vibrating screen,

belt conveyor, etc.

Inquiry

Inquiry