mobile cone crusher

-

Mobile cone crusher plant

Performance of Mobile crushing station

Compact structure, high screening efficiency, low consumption, low pollution, equipped with low-temperature preheating start-up setting.The chassis of the mobile crusher is a fully rigid ship structure with high strength, low grounding ratio and good trafficability. It can be well adapted to mountains and wetlands.

It adopts high-strength cast steel with stronger finishing process strength. It is made of high wear-resistant materials to reduce wear and increase the service life of vulnerable parts by more than 30%.

Advanced operating system, easy operation and accurate control, which can realize stepless walking speed.

Advantages of mobile crushing plants

mobile crushing plants are highly flexible. They can work on various terrible terrains and help customers get returns on investments quickly.

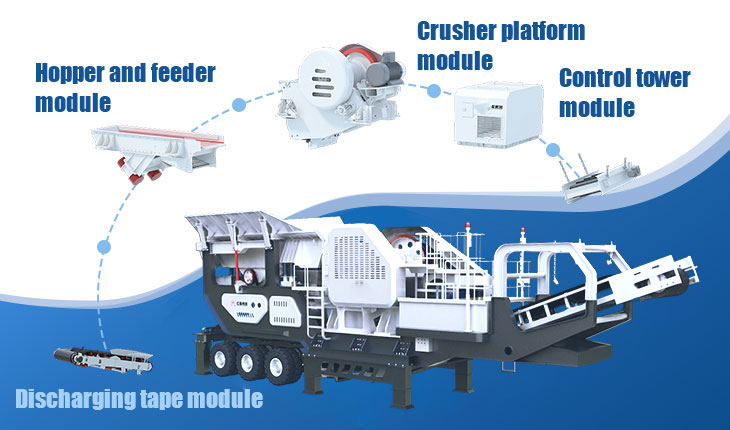

Modular and universal design concept is adopted in the design of the plant.

Production capacity: 400t/h

Maximum input size: ≤800mm

Materials to Process: limestone, coal, gypsum, seeds etc, not for very hard materials.

mobile crushers are able to be widely used in phases such as coarse crushing, intermediate crushing, fine crushing, ultra fine crushing.

Mobile crusher plant

Mobile crusher plant

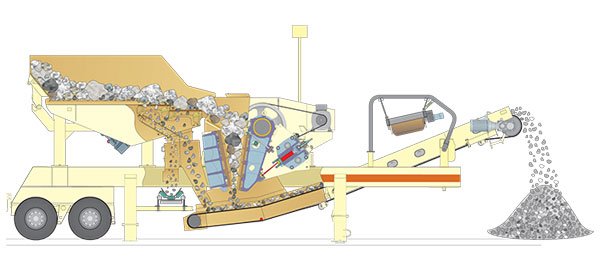

Mobile crushing station is a mining mechanical equipment that first selects materials for multistage crushing, and then screens them according to certain discharge specifications. It is widely used in metallurgy, construction, chemical industry, railway, water conservancy and other industries that often need relocation. It consists of primary crushing station, secondary crushing and screening station and belt conveyor. Crushing stations at all levels undertake different responsibilities and are independent work units.

Mobile crusher has been optimized in structure design and product portfolio, so it has more types and more flexible combinations, able to provide users with more abundant and effective portable solutions

Mobile Crusher

The equipment adopts a universal frame and a modular designed main machine, able to realize rapid upgrade and replacement, so that higher demands of production lines could be satisfied. The frame-mounted platform needs no additional investment, but only replacement of the main equipment and its accessories to upgrade and expand the scale of a stone production line.

The equipment modular design can achieve exchange of various main machines to cope with users’ changeable requirements for material process.

The equipment is provided with a preliminary screening module and an adjust-able vibrating screen, the equipment parameters can be adjusted and optimized according to Users’ field conditions to optimize the on-site produc tion efficiency.

The speed of the vehicle-mounted belt conveyor can be adjusted according to the material throughput to reduce the energy consumption. At the same time, a feedback alarm system for overload electronic control signals is additionally provided to achieve timely power-off shutdown in case of any fault.

This mobile crusher has its overall strength and applied materials upgraded, appl cable to such harsh working conditions as low temperature and vibration load.

The water-jet dust suppression device and other relevant devices are added as options to satisfy users’ various requirements.

Work flow chart of mobile crushing station

Work flow chart of mobile crushing station

When the mobile crushing station is operating, the stones that meet the feed size are uniformly transported to the jaw crusher by the feeder. After the jaw crusher is initially crushed, the screening control is carried out. Only the qualified stones can enter the next processing process, and the circuit is closed. The system can realize the cyclic crushing of materials. The finished materials are output by the conveyor for continuous crushing operation. The whole crushing process is smooth and high-yield, and the materials flow at high speed between various equipment.

The new type jaw mobile crushing plant

In addition, in terms of maintenance, the mobile jaw crusher uses a new centralized lubrication system and is equipped with a unified maintenance toolbox, so the maintenance is more convenient in the future, the cost performance is higher than other products. In a word, this mobile stone crusher plant is a widely used product whether it is a crushing and screening production line or sand making production line.

Specification of mobile crushing station

| Model | MP4060PE | MP5075PE | MP6090PE | MP75106PE | MP87106PE | MP90120PE | |

|---|---|---|---|---|---|---|---|

| Transport Dimension |

Length(mm) | 8700 | 9326 | 10700 | 12500 | 12460 | 14450 |

| Width(mm) | 2490 | 2490 | 2780 | 2900 | 3120 | 3000 | |

| Height(mm) | 3895 | 4125 | 3840 | 4450 | 4440 | 4800 | |

| Weight(t) | 17.4 | 27 | 35.4 | 60 | 60 | 82 | |

| Axle Weight(t) | 8.1 | 16 | 25 | 40.5 | 41.3 | 52 | |

| King Pin Weight(t) | 50/9.3 | 50/11 | 50/10.4 | 90/19.5 | 90/18.7 | 90/30 | |

| Jaw Crusher | Model | PE400X600 | PE500X7500 | PE600X900 | PE750X1060 | PE870X1060 | PE900X1200 |

| Feed Opening (mm) |

400*600 | 500*750 | 600*900 | 750*1060 | 870*1060 | 900*1200 | |

| Maximum Feed Size | 340 | 425 | 500 | 630 | 750 | 780 | |

| Setting Range (c.s.s) (mm) |

40-100 | 50-100 | 65-180 | 80-180 | 170-270 | 95-225 | |

| Capacity(m3/h) | 10-35 | 25-60 | 30-80 | 72-150 | 145-235 | 170-250 | |

| Feeder | Model | GZT0724 | GZT0724 | GZT0932Y | ZSW490X110 | ZSW490X110 | ZSW600X1300 |

| Volume(m3) | 3.2 | 3.2 | 7.6 | 10 | 10 | 10 | |

| Width(mm) | 2200 | 2200 | 3150 | 3000 | 3000 | 3000 | |

| Belt Conveyor | Model | B600X5.8Y | B650X5.8Y | B1000X7.0Y | B1000X7.2Y | B1000X7.2Y | B1200X8.3Y |

| Side Belt (optional) | |||||||

| Model | B400X2.7Y | B500X2.7Y | B500X2.7Y | B500X2.7Y | B650X3.5Y | ||

| Separators (optional) | Model | RCYD-6.5 | RCYD-6.5 | RCYD-10 | RCYD-10 | RCYD-10 | RCYD-12 |

| Frame Axes | Number of Axes | 1 | 2 | 2 | 3 | 3 | 4 |

mobile cone crusher plant

Specification of mobile cone crusher plant

| Category | Model | ||||||

|---|---|---|---|---|---|---|---|

| Product Name |

MP150HPC3S (1) |

MP150HPC3S (2) |

MP150HPC3S (3) |

MP150HPC4S | MP200HPC | MP200HPC2S | MP200HPC3S |

| Transport Dimension |

– | ||||||

| Length(mm) | 11840 | 13300 | 13920 | 13920 | 10000 | 13720 | 14700 |

| Width(mm) | 2780 | 2780 | 2780 | 2780 | 2780 | 2780 | 2865 |

| Height(mm) | 4360 | 4350 | 4360 | 4460 | 4160 | 4350 | 4220 |

| Weight(t) | 31.8 | 31 | 33 | 34.4 | 22.4 | 37.3 | 42.9 |

| Axle Load | 21.8 | 22 | 22.6 | 23.8 | 14.3 | 26 | 29 |

| King Pins/ Axle Load |

50/10.0 | 50/9.0 | 90/10.1 | 90/10.6 | 50/8.1 | 50/11.5 | 90/14 |

| Cone Crusher | – | ||||||

| Model | HPC150 | HPC150 | HPC150 | HPC150 | HPC200 | HPC200 | HPC200 |

| Max Feed Size | 50-160 | 50-160 | 50-160 | 50-160 | 60-180 | 60-180 | 60-180 |

| Adjustment Range of Discharge Port |

9-32 | 9-32 | 9-32 | 9-32 | 9-32 | 9-32 | 9-32 |

| Vibrating Screen |

– | ||||||

| Model | 3YK1235 | 3YK1545 | 3YK1548 | 4YK1548 | no | 2YK1860 | 3YK1860 |

| Belt Conveyor | – | ||||||

| Model | no | B800X7.2Y | B800X7.4Y | B800X7.4Y | B1000X7.2Y | B1000X8.2Y | B1000X8.2Y |

| Axis Number | – | ||||||

| Model | Biaxial | Biaxial | Biaxial | Biaxial | Biaxial | Biaxial | triaxia |

Inquiry

Inquiry