Cone type Portable Crushers(mobile crushing and screening plants) is applied to multistage crush large materials, and then screen the discharges according to their different specifications. The whole set plants is widely used to mine, building material, highway, rail way and hydropower industries, etc., finish crushing and screening operations at one time, produce required size and output for consumers.

Mobile cone crusher plant

-

Mobile cone crusher plant

-

Mobile cone crusher plant

2.he adjusting device aims at adjusting the settings of crusher quickly and easily. Adjustment is carried out via the control box, which is ideal for the occasions when the parameter of discharging hole needs to be adjusted periodically.

3.Cone type Mobile Crushing Plant mainly consists of solid frame, cone crusher, feeder , vibrating screen, conveyor belts, motors and control box.

Advantages of Jaw Crusher:

1. The discharge mode adjusting device with joint mode, is reliable and convenient. The adjustment range is large, which increases the flexibility of the equipment and can meet the needs of different customers.

2. The lubrication system is safe and reliable, the parts are easy to replace and the maintenance work is convenient.

Important parameters

Production capacity: 3-500 t/h

The maximum input size: ≤1020mm

The output size: 20-300mm

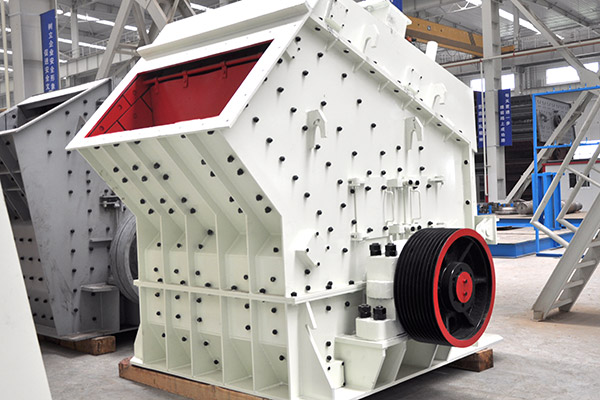

Advantages of PF impact Crusher:

The hammer bar is made of high chromium material and wear-resistant materials. After heat treatment, it has good resistance to mechanical and thermal shock.

A self-weight safety device is equipped. When unbreakable materials enter the crushing cavity, they'll be discharged automatically, and thereby the equipment can get protected.

Important parameters PF-1520

The maximum input size: 830×2050

The output size: 20-200mm

mobile crushing plants

mobile crushing plants are highly flexible. They can work on various terrible terrains and help customers get returns on investments quickly.

Modular and universal design concept is adopted in the design of the plant.

Production capacity: 400t/h

Maximum input size: ≤800mm

Materials to Process: limestone, coal, gypsum, seeds etc, not for very hard materials.

mobile crushers are able to be widely used in phases such as coarse crushing, intermediate crushing, fine crushing, ultra fine crushing.

Application of cone crushing plant

1. It is widely used in mine, coal mine, waste and construction waste recycling, earth and stone works, urban infrastructure, roads or construction sites and other site operations.2. Treat topsoil and other materials; separation of viscous aggregate; construction and blasting industries; sieve after crushing; quarrying industry.

3. Artificial sand production of river pebbles, mountain stones (limestone, granite, basalt, etc.), ore tailing and stone chips.

| Category | Model | ||||||

|---|---|---|---|---|---|---|---|

| Product Name |

MP150HPC3S (1) |

MP150HPC3S (2) |

MP150HPC3S (3) |

MP150HPC4S | MP200HPC | MP200HPC2S | MP200HPC3S |

| Transport Dimension |

– | ||||||

| Length(mm) | 11840 | 13300 | 13920 | 13920 | 10000 | 13720 | 14700 |

| Width(mm) | 2780 | 2780 | 2780 | 2780 | 2780 | 2780 | 2865 |

| Height(mm) | 4360 | 4350 | 4360 | 4460 | 4160 | 4350 | 4220 |

| Weight(t) | 31.8 | 31 | 33 | 34.4 | 22.4 | 37.3 | 42.9 |

| Axle Load | 21.8 | 22 | 22.6 | 23.8 | 14.3 | 26 | 29 |

| King Pins/ Axle Load |

50/10.0 | 50/9.0 | 90/10.1 | 90/10.6 | 50/8.1 | 50/11.5 | 90/14 |

| Cone Crusher | – | ||||||

| Model | HPC150 | HPC150 | HPC150 | HPC150 | HPC200 | HPC200 | HPC200 |

| Max Feed Size | 50-160 | 50-160 | 50-160 | 50-160 | 60-180 | 60-180 | 60-180 |

| Adjustment Range of Discharge Port |

9-32 | 9-32 | 9-32 | 9-32 | 9-32 | 9-32 | 9-32 |

| Vibrating Screen |

– | ||||||

| Model | 3YK1235 | 3YK1545 | 3YK1548 | 4YK1548 | no | 2YK1860 | 3YK1860 |

| Belt Conveyor | – | ||||||

| Model | no | B800X7.2Y | B800X7.4Y | B800X7.4Y | B1000X7.2Y | B1000X8.2Y | B1000X8.2Y |

| Axis Number | – | ||||||

| Model | Biaxial | Biaxial | Biaxial | Biaxial | Biaxial | Biaxial | triaxia |

Inquiry

Inquiry