What type of crusher do you offer?

we are capable of providing crushers for your ores. We have PE&PEW crushers, CS&HP crushers, hammer crusers, roller crushers and ball mill for mining crushing. They are reliable and efficient with high crushing ratios.In order to recommend suitable ones for you, please confirm information above.

1. Capacity: 1 tons per hour, 5 tons per hour at most, right?.

2.How big is your ore before crushing, 200 mm, 500 mm or bigger?

3.How small is your final product after crushing? 0-10mm?

After you confirm those detailed information, our engineers will recommend suitable machines for you.

Jaw crusher for sale

-

vibrating screen in crusher stationary

-

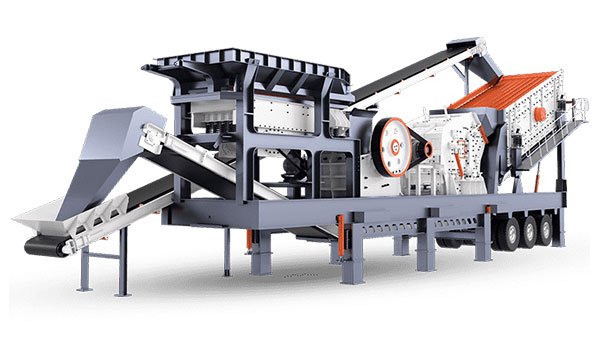

Jaw crusher stationary production line

Advantages of Jaw Crusher:

1. The discharge mode adjusting device with joint mode, is reliable and convenient. The adjustment range is large, which increases the flexibility of the equipment and can meet the needs of different customers.

2. The lubrication system is safe and reliable, the parts are easy to replace and the maintenance work is convenient.

Important parameters

Production capacity: 3-500 t/h

The maximum input size: ≤1020mm

The output size: 20-300mm

The crushing plant has brought new prospect to mining industry. Traditional crushing mining machine has high cost, and personnel safety can not be guaranteed. So mine accidents occur frequently in recent years. Fortunately, with the successful development of crush plant, mining machinery shows the trend of digitization, integration and knowledge. And crusher plant has becoming the leader of mining machinery.

In addition, crush plant mainly consists of mobile crushing screening plant and fixed crushing plant. Here, Hamac will give you the detailed description of this two kinds of crusher plant machines.

The Following project machine list is just for your reference, if you want to know more of Stone crushing plant, pls contact us!

| No. | Equipment | Model | Motor (KW) | Number |

| Hopper | LC2000X3000 | 1 | ||

| I | Vribrating Feeder | GZD604 | 1.5 | 1 |

| II | Jaw Crusher | PE400x600 | 30 | 1 |

| III | Impact Crusher | PF1007 | 55 | 1 |

| Ⅳ | Vribrating Screen | 3YK1236 | 7.5 | 1 |

| Belt | ||||

| No. | Name | Length (m) | Motor (KW) | Number |

| B1 | B500 | 15 | 5.5 | 1 |

| B2 | B500 | 12 | 3 | 1 |

| B3 | B500 | 18 | 5.5 | 1 |

| B4 | B500 | 19 | 5.5 | 1 |

| B5 | B500 | 15 | 5.5 | 3 |

Schematic diagram of production line layout

Mobile Crushing Plant:

We all know that urban pollution is becoming more and more serious and the reuse of renewable energy is limited. With the strengthening of environmental awareness, we have paid more attention to urbanization pollution. Mobile crushing plant turns ‘garbage’ into ‘energy’, and it can effectively process urban constructions.

Besides, Hamac’s mobile crushing plants for sale adopt advanced producing technology and designing concept, so they have many superior advantages:

1. The installation form of the entire set of equipments can not only eliminate the installation of complex site infrastructure, but also reduce the material loss and time loss. The reasonable and compact space layout of the set of equipments can improve the flexibility of site stationing.

2. This kind of crushing and screening equipment is flexible and the car chassis is high, so it is convenient for running on the ordinary highway and the rugged road in crushing areas. It saves time for stationing at the construction site. Moreover, it is easier to locate in the reasonable construction area, and it provides more flexible space and reasonable layout configuration for overall crushing process.

3. The whole set of stone crusher plant can work individually or work together by combining flexibly on the basis of coarse crushing and fine crushing.

4. The plant can greatly reduce the transportation costs, because materials need not to be transported to next process location remotely. All the machines used in the whole process are in the same place.

5. Unloading hopper also has some excellent features. In addition to providing the flexibility of diverse configuration for the material delivery, unloading hopper can also supply power to the process system specifically.

Mobile Impact Plant

| Category | Model | |||

|---|---|---|---|---|

| Mobile Impact Plant | MP1010PF(3S) | MP1210PF(3S) | MP1214PF(3S) | MP1315PF(3S) |

| Transport Dimension | ||||

| Length(mm) | 10800 | 11400 | 11490 | 12000 |

| Width(mm) | 2780 | 2780 | 2880 | 2865 |

| Height(mm) | 4170 | 4300 | 4470 | 4500 |

| Weight(t) | 30 | 39.3 | 46.3 | 42 |

| Axle Weight(t) | 19 | 24.6 | 30.1 | 29 |

| King pin Weight(t) | 50/11.0 | 90/14.7 | 90/16.2 | 90/13.0 |

| Impact Crusher | ||||

| Model | PF1010 | PF1210 | PF1214 | PF1315 |

| Feed Opening(mm) | 400*1080 | 400*1080 | 400*1430 | 860*1520 |

| Maximum Feed Size | 400 | 500 | 500 | 600 |

| Capacity(t/h) | 50-80 | 70-120 | 100-180 | 160-250 |

| Feeder | ||||

| Model | GZT0724 | GZT0932 | ZSW3895 | GZT1148 |

| Feed Hopper Volume(m3) | 3.2 | 7.6 | 9 | 10 |

| Hopper Width(mm) | 2200 | 3150 | 3290 | 3000 |

| Main Belt Conveyor | ||||

| Model | B800X7.0Y | B800X7.5Y | B1000X7.2Y | B1000X7.2Y |

| Side of the Belt Conveyor | ||||

| Model | B400X2.7Y | B500X2.7Y | B500X2.7Y | B500X2.7Y |

| Separators (optional) | ||||

| Model | RCYD-8.0 | RCYD-8.0 | RCYD-10.0 | RCYD-10.0 |

| Frame Axes | ||||

| Number of Axes | 2 | 2 | 2 | 3 |

Fixed Crushing Plant:

The fixed crush plant also called fixed crushing and screening plant. Moreover, it includes fully fixed crushing plant and semi – fixed crushing plant.

1. Fully fixed crush plant. It is usually fixed in a specific place. In most cases, it is located in the surface of the open pit mine, and some are located in the bottom of the open pit. The fully fixed plant is the type which is mainly adopted before 1980s. It needs long construction time and high cost. Besides, with the extending of mining range, the transport distance will increasing, and the car freight will also increasing.

2. Semi – fixed crushing plant. It is usually composed of crushers, belt conveyors and other equipments, and its height is about 30m. When the whole set of crushing screening plant needs to be moved to a new location, every part needs to be dismantled, and the individual part is transported by the carrier and reassembled in the new location. In general, the location period is about 10 years, and the transfer work will take about a few weeks.

Compared with the mobile crusher plant design, the fixed crush plant has no tires. In view of the present situation of construction waste disposal, the mobile crush plant has obvious advantage.

However, with the maturity of construction waste processing technology, the fixed crushing plant will also have a very good development prospect. Both fixed plant and mobile plant have their own superior features, you should choose a kind of crushing plant according to your actual needs. If you are not sure which one to choose, you can contact Hamac. We will give you the best solution.

Crushing Plant Layout:

Crusher plant is mainly consists of jaw crusher, impact crusher, cone crusher, sand vibrating screen, belt conveyor and other equipments. And it is a multistage combination of machines. In order to adapt to different working environments and users’ demands, its layout has several kinds of forms.

According to the requirements of different crushing operations, crushing plant can be combined into two processes : “first crush and then screen” and “first screen and then crush”. The crushing plant can be combined into coarse crushing system and fine crushing system according to customers’ actual needs, it can also be combined into three stages: coarse crushing, crushing and fine crushing. Moreover, it can also work individually and its layout has great flexibility.

Working Principle of Crushing Screening Equipment:

As for crushing plants’ working principle, Hamac’s experts give customers the explanation. Materials in the bucket elevator can be evenly transported to the crushing plant by the feeder. After materials primary crushed by crushing machine, the crusher and the circular vibrating screen can form a closed circuit system to achieve materials’ cyclic crushing. The materials, which meet the size requirements, can be discharged. We can also remove the circular vibrating screen on the basis of the actual production needs. In this way, materials can be primary crushed directly, and then be processed by crusher and other crushing machines.

In mining machinery industry, there are many crushing plant manufacturers. And all of them can produce many types of crusher machines. Then where should you purchase a crush plant? Here, I recommend you Hamac Group. Hamac, a professional mining machinery supplier, has many kinds of crushing and screening plants for sale, such as: crawler crushing plant, jaw type crushing plant, impact mobile crushing plant and so on.

Inquiry

Inquiry